It’s a well-known fact that the better part of the most significant industries heavily relies on the sheet metal fabrication industry and its products. These industries include construction, automotive, aerospace, and electronics, to name a few.

And with the fluctuating price of other raw materials and the ability to cut down on overhead by using metal when applicable, it certainly seems like the sheet metal fabrication industry will be here and stay relevant for the foreseeable future.

This fabrication technique encompasses creating different final structures from raw metal materials through welding, cutting, burning, machining, and assembly. These processes are geared towards creating vital components and final products necessary for the industries mentioned above.

So what about the future of sheet metal manufacturing? Both industry insiders and large-scale manufacturers are eager to know if we are about to see some changes in this industry or if we are stuck with what we have today.

Luckily, our team of industry professionals conducted thorough research on the matter and got some answers. Within each following paragraphs, we present to you the four trends set to drive the sheet metal fabrication industry in the next ten years and beyond.

Table of Contents

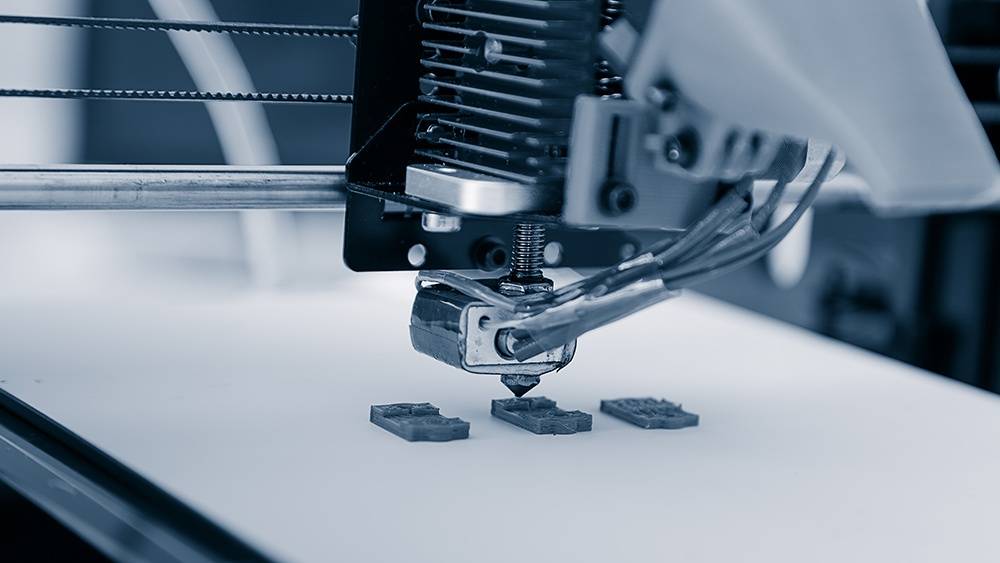

1. Increased Automation In The Manufacturing Phase

Automation is a global phenomenon that’s not only prevalent in the sheet metal fabrication industry but other industries and sectors as well. It’s considerably improving and simplifying the process of cutting and bending sheet metal workpieces, and because of this, manufacturing operations became more efficient, and errors in production were minimized.

Thanks to manufacturing process automation, metal fabricators can now run their daily operations without any human intervention, saving significant amounts of money on human resources and production errors.

A couple of machines have covered some way for robotization in the sheet metal invention manufacturing, such as CNC machines that only need the instructions from a CAD file to perform different cuts. Some of the cutting tools utilized by these machines include plasma, laser, flame, tube laser, and water-jet cutting technology.

There are an unmatched precision and accuracy with laser-cut steel or steel-cut using any of these different technologies that give it an edge over those cuts utilizing manual operations, for example. Besides precision and accuracy, these modern-day cutting technologies also make it possible to work on intricate patterns, all without the need for human interference.

Apart from the machines, another thing worth mentioning when it comes to automation is the plethora of collaborative robots or cobots. While robots work independently, cobots are in the first place designed to work with humans. Even though the use of cobots in the sheet metal fabrication industry is still in its early stages, expect this trend to quickly become the benchmark for the most successful metal fabricators in the world.

Photo from Medium

2. Inflated Steel Structures

While the other trends on this list are somewhat more concrete and applicable to nearly all sheet metal fabricators, other industry trends portray the sheet metal fabrication industry’s future potential.

One of these groundbreaking trends is the possibility to develop inflated steel structures, which demonstrates what’s possible to achieve with sheet metal. The fabrication technique of boosting steel may become a sheet metal fabrication technique utilized more universally in the next ten years and beyond.

Polish architect Oskar Zieta explained this sheet metal fabrication technique for Architect Magazine in 2019: The process is initially named FiDU, short for “Freier innen Druck Umformung” or free inner pressure forming. This manufacturing approach is best-displayed in the Plopp Stool construction, a three-legged chair built entirely of thin steel sheets.

His company Zieta Prozessdesign manufactures the chair by laser-cutting templates out of a steel workpiece, welding sheets mutually on these edges, and inflating them from a single point like a balloon. Imposingly enough, the chair can support a load of two tons.

People can even occupy Oskar Zieta’s products. That’s why he developed a curvilinear vault called the NAWA pavilion, along with other sheet metal projects, to showcase the possibilities of this particular fabrication technique that we expect to become relevant in the next couple of years.

Photo from Zieta Prozessdesign

3. Mass Implementation Of Enterprise Resource Planning (ERP) Systems

Industry experts expect more and more manufacturers in the metal sheet fabrication industry to implement enterprise resource planning systems as time passes by.

Since most of the sheet metal manufacturing companies aren’t limited to providing their services to local markets but have clients and operations from all over the world, it can be overwhelming for them to manage both their local and global processes and handle their materials and suppliers without the use of an ERP system.

ERP software will undoubtedly help sheet metal manufacturing companies efficiently manage their daily business activities like project and risk management, accounting, procurement, and supply chain operations.

4. Enhanced Cybersecurity Efforts

Another noteworthy trend to follow in the sheet metal fabrication industry is the upcoming incorporation of cybersecurity systems into the machinery and the whole network utilized by sheet metal fabricating machinery.

In the following years, it will be crucial to secure the sheet metal manufacturing systems’ data and processes to minimize, if not eliminate, the risk of business disruption.

Like all other machines, CNC machines can also be hacked and threatened by malware and other viruses, so manufacturers who tend to stay at the top of their game will have to speak to cybersecurity professionals to protect their equipment and bolster their security systems.

Photo from Worcon

5. Final Thoughts | Sheet Metal Fabrication Industry

To finish things up, the sheet metal fabrication industry trends as illustrated above are only a small portion of the technologies and advancements you can expect to be prevalent in this industry for the upcoming decade.

Nonetheless, since numerous technological innovations are constantly emerging, other trends may soon be uncovered as well.

Make sure to follow the trends as they emerge, and rest assured that the sheet metal fabrication industry will be ready to answer the demands of the other industries that rely on it.

Tech Trends

Related posts

Leave a Reply Cancel reply

Hot Topics

Categories

- Ads (5)

- Animes (25)

- Artificial Intelligence (AI) (35)

- Augmented Reality (AR) (10)

- Automotive (9)

- Bitcoin (16)

- Blockchain (24)

- Business (244)

- Business Intelligence (3)

- Cloud Computing (23)

- Computer (128)

- Concrete Technology (1)

- Cryptocurrency (10)

- Cybersecurity (42)

- Data Science (9)

- Database (4)

- DevOps (6)

- Digital Marketing (76)

- Digital Workplace (14)

- Ecommerce (1)

- Education (28)

- Electric Vehicle (EV) (1)

- Electronics & Hardware (17)

- Entertainment (42)

- Fabrication (3)

- FAQ's (1)

- Finance & Marketing (47)

- Gadgets (35)

- Games (8)

- Gear (29)

- HTTPS (1)

- Industry (46)

- Information Technology (90)

- Internet (413)

- Internet of Things (IoT) (41)

- Job (25)

- Machine Learning (6)

- Marketing (92)

- Mobile Apps (21)

- Movies (11)

- Natural Language Processing (6)

- News & Trends (109)

- Programming (4)

- Science & Technology (235)

- Security (81)

- SEO (56)

- Services (36)

- Social Media (73)

- Software (99)

- Sports (1)

- Technology (306)

- Telecom (6)

- TikTok (5)

- Tours & Travels (9)

- Uncategorized (11)

- Virtual Reality (VR) (7)

- VoIP (4)

- Web Technology (42)

- Workforce (17)

- Workspace (6)

Stay connected